SGS CPU is Moving

Our Clinical Pharmacology Unit in Belgium is moving to a new building.

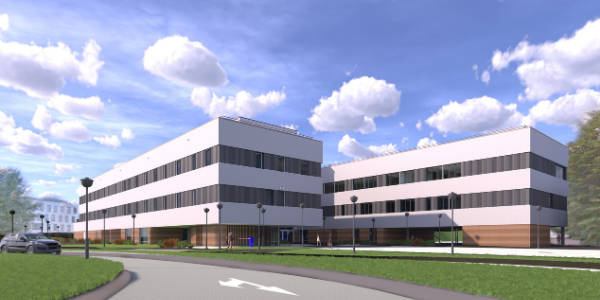

To increase capacity and capabilities, the SGS Clinical Pharmacology Unit (CPU) in Belgium is moving into a brand-new building located in Edegem, in the grounds of the University Hospital of Antwerp (UZA), a 15-minute drive from its current location.

You can find our new facility at:

Clinical Pharmacology Unit

Drie Eikenstraat 655

Building J

B - 2650 - Edegem

Belgium

As part of the SGS Health Science division, Clinical Research has more than 40 years’ experience offering clinical research services and bioanalytical testing for phase I to IV clinical trials, with a specialization in infectious diseases, respiratory diseases and vaccines.

Our CPU has been actively performing early phase clinical trials for over 30 years and is testing therapeutic drugs and vaccines on healthy volunteers and small groups of patients. Currently the CPU is located in the hospital of ZNA Stuivenberg in Antwerp, Belgium.

In collaboration with the Antwerp University Hospital, this new unit is being built to increase capacity and capabilities for future clinical studies. The move to the new unit is planned for summer 2021.

Improvements

Increased bed capacity including an expanded isolation unit for Human Challenge Trials

We are increasing our bed capacity from 88 to 110 beds:

- One high visibility room including 8 beds added

- 56 bed ward available

- 46 individual rooms (two wards) that can be used for Human Challenge Trials or other specialty approaches

Collaboration with the University Hospital in Antwerp (UZA)

- Direct connection to the UZA emergency room

- Close collaboration with UZA/UA specialists and techniques which means we have direct access to expert and more technologies

Increased focus on sustainability

- Automatic water cranes, boost heat pump for sanitary hot water & heating by climatic caps

- Eco-friendly accommodation, including climate ceilings, a green roof, and solar panels

- Maximum waste separation and use of biological cleaning products

Increased production facility capabilities and capacity

- Designed to minimize the opportunity for extraneous contamination, cross contamination, the risk of errors and any adverse effect on the quality of products

- Changing rooms are designed as airlocks and used to provide physical separation of the different stages of changing and to minimize microbial and particulate contamination of protective clothing

- Presence of a fully continuous electronically monitored cleanroom (particulate monitoring , temperature, humidity and overpressure)

- Increased pharmacy capabilities and capacity including Class D-C-B preparation rooms, more/different on-site manufacturing approaches and the possibility of manufacturing sterile products under aseptic conditions

Centrally located laboratory for sample management

To cope with the more complex sample handlings (complexity and number of samples) our new facility enclosed an increased lab capacity. Next to 2 labs dedicated to specific wards all samples can be handled in our new centrally located large sample preparation laboratory embedded in the heart of the unit.

- Centrally located

- Enlarged capacity

- Equipped to handle complex PK/PD sample management (eg. PBMC, specific sample protocols, Acid cabinets, LAF cabinets)

- Larger Storage capacity for samples, direct accessible from the lab

Advantages for volunteers

The new facility has a modern interior creating a more homely atmosphere instead of a hospital-like feeling to offer our study participants a comfortable stay and overall study experience.

- Spacious and bright rooms for overnight stays

- Large restaurant and lounge area including multiple corners to spent leisure time

- Open air terrace

- Separate screening and ambulatory ward at the ground floor increasing efficiency of these visits

- Good accessibility both by car and public transport

On the move

Read on for the latest updates.

June Aug

- Installation clean rooms

- Transfer of production facility equipment

- Validation of production facility equipment

- Transfer of screening equipment and first screening at the new facility

April and May

- Landscaping (main entrance both sides)

- Placement of doors, windows and fixed furniture in volunteer/patient wards

- Installation of cleanroom walls

- Continued painting and flooring in the entire building

- Placement of ceilings

- Technical installations

March

- Creation of ‘example’ 1-person and 2-person bedroom

- Start flooring in the 1-person bedrooms

- Start painting and tiling of walls

- Placement of elevator

- Cleanrooms : Placement of main air channels

- Placement of heat pump

- Start placement of sinks

- Start Landscaping

February

- Finalization of outside building

- Continuation installation techniques

- Start placement of ceilings on the top floor (office, and single-bedrooms)

- Dry blowing of the building

January

- Continuation of placing of internal walls and techniques

December

- Placement of interior walls in drywall

- Technical installation (HVAC and electricity)

November

- Start facade finishing: insulation and installation of ceramic plate material

- Blower test windproof

October

- Completion of the structural work

- Completion of placement of exterior windows and doors